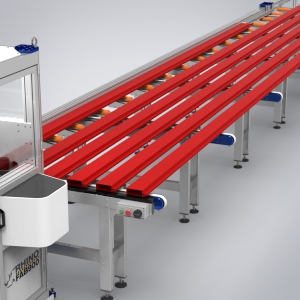

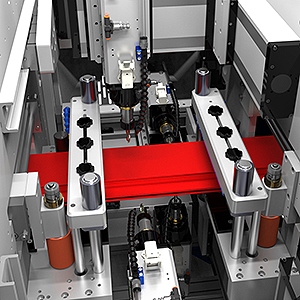

The RhinoFAB 1100 Machining Center takes storefront and curtain wall material and pushes it through a fabrication center where it can drill or rout from the top, bottom and front to create fabrication holes and shapes and then a down cut miter saw to trim or cut the product to the required size.

The RhinoFAB 1100 takes direct feed from the PartnerPak+ and Glazier Studio line of estimating and fabrication software.

KEY FEATURES:

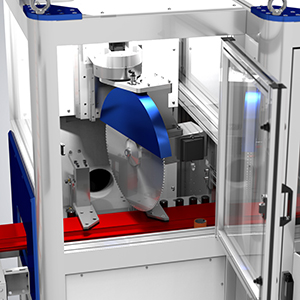

- 18-21” Down Cut Miter Saw 45°-135°

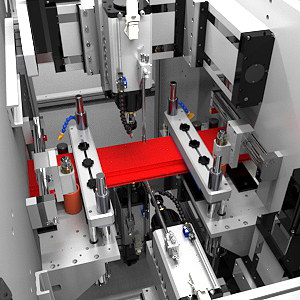

- Standard 3 Axis Machining

- (Top, Bottom & Front)

- Process up to 10” x 5” Profiles

Standard 3 Axis Machining

18-21” Down Cut Miter Saw 45°-135°

Automatic Material Load/Feed

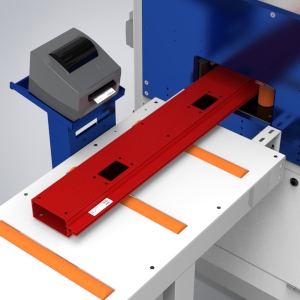

Labeling for Material Sorting

Optional 4 Axis Machining

The fastest way to grow your business with the leader in Technology