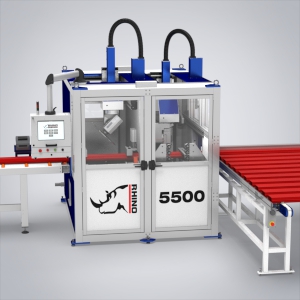

The RhinoFAB 5500 Machining Center takes storefront and curtain wall material and pushes it through a fabrication center where it can drill or rout from the top, bottom and front to create fabrication holes and shapes and then a compund bevel and miter saw to trim or cut the product to the required size.

The RhinoFAB 5500 takes direct feed from the PartnerPak+ and Glazier Studio line of estimating and fabrication software.

KEY FEATURES:

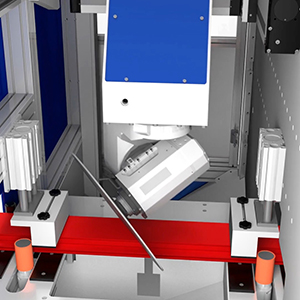

- Compound Bevel & Miter Saw 45°-135°

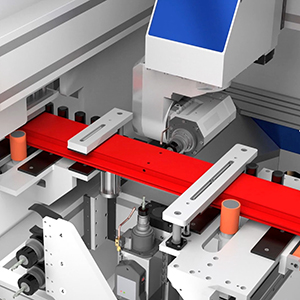

- Uni-Head CNC Rotating Spindle (Drill, Rout, Countersink, Tap)

- (Top, Bottom, Back & Front)

- Process up to 10” x 5” Profiles

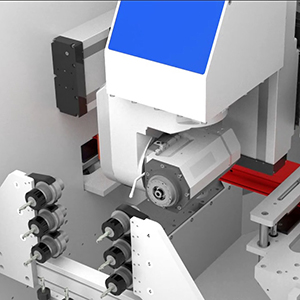

- Auto tool changer

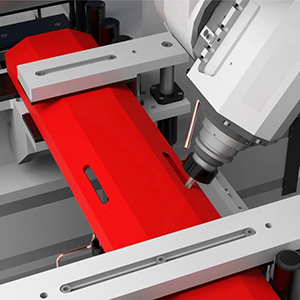

Uni-Head CNC Rotating Spindle

Compound Bevel & Miter Saw 45°-135°

Automatic Tool Changer

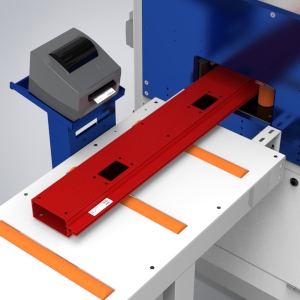

Labeling for Material Sorting

Maching on all sides

RHINOFAB 5000 SERIES VIDEOS

The fastest way to grow your business with the leader in Technology